ential for a MATILDA to sail well and safely.

ential for a MATILDA to sail well and safely.One of the main purposes of spreaders is to create a more open angle for the shroud attachment at the top of the mast because if the angle is too acute [less than 12degrees], then much of the load on the spreader is converted to excessive compression loading on the mast. The preferred angle is 12degrees or greater.

Spreaders can also be used to bend the mast but on a MATILDA the mast is not limber enough to be affected by the spreader unless you are out in a real gale.

Another objective is that the spreader should be attached to the shroud at an angle that bisects the shroud above and below the spreader/shroud attachment point. Spreaders that are level to the horizon look lifeless, dowdy[love that word] and can be dangerous as the pressure exerted on them by the shrouds can force the outer end down the shroud, causing reduced tension on the shroud as well when you come about, your shroud could, literally, be waving in the wind.

Another factor to consider is the practice of attaching a pulley to the underside of a spreader, towards the outer end, for running up pennants, flags, burgees, etc. Do so with caution, as even a small pull on most spreader/shroud attachment will cause the spreader to slowly creep down the shroud. Excercise caution, when raising pennants, etc., if you adhere to this practice.

So, I hope I have convinced you that it is extremely important that the outer end of the spreader be firmly attached to the shroud.

Here are photos of a system we have utilized for several years, that ensures that our outer ends of our spreaders remain firmly fastened to our shrouds.

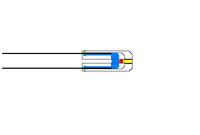

[Enlarge this photo to appreciate the complexities of the components]

Blue-aluminum plug fits inside spreader[pushfit inside spreader]

head is same O.D. as spreader[radius corners well so that shroud does not go over sharp corners]-Core drilled out to allow 1/8" wall inside spreader[to allow rivet head to expand]

Yellow-1/8"stainless pipe plug-27T.P.I.

Red-5/32" shroud wire

Green-3/16" aluminum pop rivets. They can easily be drilled out to remove shroud, if necessary.

Cap is made from aluminum-1/4" larger than spreader O.D. to

allow 1/8" wall around spreader

allow 1/8" wall around spreader5/32" slot cut top and bottom to allow shroud to be installed.

[Use caution when tapping plug hole so that plug traps wire securely before plug threads [tapered] bottom against cap threads].

Cap body bored out to spreader O.D. to depth of slot.

[Radius end of cap well so that fore-sails and main sail do not rub against sharp corners].

Thanks for finally talking about > "SPREADER ENDS" < Loved it!

ReplyDeleteTake a look at my website; best selling mens cologne

I'm amazed, I have to admit. Seldom do I come across a blog that's equally educative and entertaining,

ReplyDeleteand let me tell you, you've hit the nail on the head.

The problem is an issue that not enough folks are speaking intelligently about.

I am very happy I found this in my hunt for something regarding this.

Also visit my homepage ... this domain