......................Image- Courtesy of Les Leonhardt........................

????What Constitutes A Modified Matilda???[Status as of Sept. 30/04]

OR

Things I have learned about a MATILDA 20

Efficiency

....Cosmetic

........SafetyX........ #1. Install inboard jib sheet fairlead track [13 degrees rather than 25 degrees] and install Harken cam cleats

X........ #2. Install 12" Leader on jib tack

X........ #3. Fair and apply 2 part paint to centerboard and bulb plus rudder [Awlgrip Forest

Green]

........ X#4. Revise centerboard raising/lowering pulleys to reduce wear on front centerboard guide as well as ensure safety bolt engagement

........X #5. Install safety limit strap on centerboard

....X X #6. Replace wooden handrails with stainless handrails

X X X #7. Install 15" windex wind indicator on proper mount

X.... X #8. Tension standing rigging to ensure a taut rig

....................................... 5/32" 1x19 wire-B.S. =3300lbs

..................Forestay 15% of breaking strength = 500lbs

.........Upper shroud 15%. "......... ".............. " .....= 500lbs

.........Lower shroud 10%. " .........".............. " .....= 330lbs

....................Backstay 5% ."......... ".............. " .....= 165lbs

X. ....X #9. Make new bushings for rudder pintles and gudgeons

X...... #10. Install spring on rudder to ensure leading edge of rudder blade is at 90 degrees to

waterline

...X.... #11. Replace window gaskets

...X.... #12. Replace windows with lexan

...X.... #13. Paint hull from waterline to gunnels with 2 part paint [Awlgrip Forest Green]

...X. ...#14. Install name on hull

X...... .#15. Move gas tank to starboard cockpit locker

........X#16. Make bracket to install life ring on stern pulpit

...X.... #17. Paint cabin entrance trim and door

X....... #18. Replace loose slugs on mainsail

X....... #19. Make boom downhaul functional

X....... #20. Replace genoa track so that genoa track fairleads function

X X X #21. Make caps for ends of spreaders so that they do not droop

...X.... #22. Fill nicks and gouges in gunnel with gelcoat

...X.... #23. Remove winch, organizer and eye straps from cabin top

...X.... #24. Fill bolt holes with epoxy

...X. X#25. Replace rotted wood on motor mount with plastic

........X#26. Replace wiring and bulbs on mast

...X.... #27. Replace broken screws in hatch cover slides

X X.. .#28. Make a Mobius Brummel splice to attach jib clew shackle to jib sheet

....X ...#29. Replace tiller with custom tiller from Nordica

........X#30. Make new motor lock so that motor mount functions properly

SAILING TO WINDWARD

Sailing to windward is an art and to a large degree is what sailing is all about. The shape of sailboats is even dictated by this observation. The most popular type of sail plan is the Bermudian-rigged sloops because they are so efficient to windward.

Sailing with the wind behind you, most boats tend to be relatively similar in performance. The exception is that if you have managed to present more sail area to the wind, e.g. spinnaker, whisker pole etc., you will gain marginally on your opponent. When sailing down wind, sail area is the most critical component. EVEN A HAYSTACK CAN SAIL DOWNWIND.

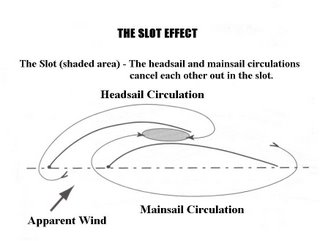

But when sailing to windward, sail shape and the sails’ relationship to one another are much more critical and demanding, but ,OH, so rewarding. When sails are properly set and performing well, there is a tremendous improvement in speed and pointing ability over an improperly rigged set of sails. The sum of two sails, properly trimmed, to the wind strength can be more than the total of each individual sail. In other words, if the mainsail provides 100 lbs. of forward thrust by itself and the jib provides 50 lbs. of forward thrust by itself, when they are rigged and trimmed to properly complement each other, you might end up with 200 lbs. of forward thrust. THIS IS THE "HOLY GRAIL" OF SAILING.

Many different styles of sailboat, e.g. sailboards, catamarans, are faster on a beam and broad reach than sloop rigged mono-hulls, but if they are asked to compete around a race course, the sailboards and catamarans are at a great disadvantage because of their lack of ability to point well.

So where does a Matilda fall in the grand scheme of things? Because of its broad beamy hull, a Matilda’s strength is its great stability. On lesser boats, if you step on the gunnel, the boat is likely to tip over, but on a Matilda, she says, "Welcome aboard and sit yourself down, if you please".This tremendous stability is what endears many Matilda owners to their pride and joy. This fact also carries over to the crew who think that nothing can go wrong when sailing a Matilda because they are so stable.. This stability is also a great asset when it comes to beam reaching and broad reaching, especially with a big genoa . It is really exhilerating to be on a Matilda with sails properly set, on a close reach, and when the centreboard is pulled up, tear off onto a screaming plane. (Try that, you keel boats.)

A case in point is, at the

Wildwood Sailing Club, when we have the wind out of the northwest, [the prevailing wind direction, in our area] running down the lake is a piece of cake, and if you happen to "go around the bend", that is head off on an easterly beam reac

Wildwood Sailing Club, when we have the wind out of the northwest, [the prevailing wind direction, in our area] running down the lake is a piece of cake, and if you happen to "go around the bend", that is head off on an easterly beam reac h, you can really enjoy a relaxing sail right down to the bridge at the end of the lake. But now the fun begins. When you turn around to head back to the club, the first section, on a beam reach, goes reasonably well until you hit" THE

h, you can really enjoy a relaxing sail right down to the bridge at the end of the lake. But now the fun begins. When you turn around to head back to the club, the first section, on a beam reach, goes reasonably well until you hit" THE  BEND". Because the wind, coming straight down the lake from the northwest, hits the "WALL OF GREEN" [ trees surrounding the lake shore], the wind bends around the corner producing a westerly shift to the wind at the bend. Sailing into this shift forces you to change from a beam reach to a close reach (pointing) and your progress around the bend is impeded. If your boat does not point well, you can spend a long time (it seems like forever) making progress around the bend and then, when you finally do get around the bend, you are faced with a beat to windward back to the club.

BEND". Because the wind, coming straight down the lake from the northwest, hits the "WALL OF GREEN" [ trees surrounding the lake shore], the wind bends around the corner producing a westerly shift to the wind at the bend. Sailing into this shift forces you to change from a beam reach to a close reach (pointing) and your progress around the bend is impeded. If your boat does not point well, you can spend a long time (it seems like forever) making progress around the bend and then, when you finally do get around the bend, you are faced with a beat to windward back to the club.This lack of pointing ability reflects poorly on the owners of Matildas in general. Prior to acquiring our Matilda, we would leave the end of the lake at the same time as a Matilda, and be back at the club in one quarter of the time it took the Matilda to return to the club. This self congratulation was not entirely due to superior sailing skills but to the dramatic difference in the pointing ability of our two completely different crafts - the Matilda, broad beamed and poorly rigged for pointing and our KD (http://kerry-dancer.blogspot.ca/), a highly refined pointing machine.

Upon acquiring the Matilda, I pondered what could cause the tremendous difference in pointing ability between the two crafts. It finally dawned on me that the chord of the foresail on a Matilda was the main culprit, aside from the difference in the hulls. That was when I decided that something had to be done to improve the pointing ability of our Matilda, as I was not content to go from leading the pack to bringing up the rear. It also dawned on me that people who owned Matildas can be incorrectly looked down upon for their lack of sailing abilities when their boat is actually the problem. This "defect" in the boat causes many Matilda owners to forgo the pleasures of sailing to windward and to be content with beam and broad reaching, and if they do go around the bend, they decide that motoring back to the club is the "GENTLEMANLY" thing to do.

So once the problem has been defined, how do we go about correcting it?

The original position of the jib sheet fairlead anchor, on the gunnel track results in a chord angle of 24degrees. Much too open to properly complement the main sail, when going to windward. [It is almost impossible to ever backwind the main sail with the jib fairlead in it's original position]. By moving the jib sheet fairleads to the cabin top, we could get close to the desired chord angle of 12degrees. It was also necessary to add a leader to the tack of the foresail [to raise the sail] so that the cabin top fairleads could be utilized. We also added cam cleats for the jib sheets, which make sheeting the jib a "piece of cake".

This installation has greatly improved the pointing ability of our MATILDA and has resulted in many a surprised look from skippers, we have brushed against, who have always thought that MATILDAS could not go to weather well.

All in all, a very worthwhile modification!!!

P.S. JIB TACK LEADER and INBOARD JIB SHEET FAIRLEAD TRACK postings also contain information concerning SAILING WELL TO WINDWARD.

Nowhere has it been mentioned how critical a good wind indicator is to

.jpg) achieving good windward performance. Others manage to sail well with wind indicators on their shrouds or a ribbon from the masthead and I compliment them on their ability to read the wind. However, a WINDEX 15, with the vanes set to the appropiate angles for a MATILDA (notice special bracket for mounting wind indicator), allows a helmsperson to notice and adjust for the slightest change in wind direction [THE WIND IS NEVER CONSTANT- THE ONLY THING CONSTANT ABOUT THE WIND IS THAT IT IS CONSTANTLY CHANGING]. A characteristic of the most proficient sailors is that they monitor the wind direction, frequently.

achieving good windward performance. Others manage to sail well with wind indicators on their shrouds or a ribbon from the masthead and I compliment them on their ability to read the wind. However, a WINDEX 15, with the vanes set to the appropiate angles for a MATILDA (notice special bracket for mounting wind indicator), allows a helmsperson to notice and adjust for the slightest change in wind direction [THE WIND IS NEVER CONSTANT- THE ONLY THING CONSTANT ABOUT THE WIND IS THAT IT IS CONSTANTLY CHANGING]. A characteristic of the most proficient sailors is that they monitor the wind direction, frequently.In my opinion, a sail boat that goes to windward well is a much more enjoyable craft to sail and results in a much safer, faster and more responsive vessel than the MATILDAS as they came from the builder.

.jpg)

.JPG)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)